One of the greatest problems that the world is facing today is that of environmental pollution, increasing with every passing year and causing grave and irreparable damage to the earth. Environmental pollution consists of five basic types of pollution, namely, air, water, soil, noise and light

Air pollution is by far the most harmful form of pollution in our environment. Air pollution is cause by the injurious smoke emitted by cars, buses, trucks, trains, and factories, namely Sulphur dioxide, carbon monoxide and nitrogen oxides. Even smoke from burning leaves and cigarettes are harmful to the environment causing a lot of damage to man and the atmosphere. Evidence of increasing air pollution is seen in lung cancer, asthma, allergies, and various breathing problems along with severe and irreparable damage to flora and fauna. Even the most natural phenomenon of migratory birds has been hampered, with severe air pollution preventing them from reaching their seasonal metropolitan destinations of centuries.

Chlorofluorocarbons (CFC), released from refrigerators, air-conditioners, deodorants and insect repellents cause severe damage to the Earth’s environment. This gas has slowly damaged the atmosphere and depleted the ozone layer leading to global warming.

Water pollution caused industrial waste products released into lakes, rivers, and other water bodies, has made marine life no longer hospitable. Humans pollute water with large scale disposal of garbage, flowers, ashes and other household waste. In many rural areas one can still find people bathing and cooking in the same water, making it incredibly filthy. Acid rain further adds to water pollution in the water. In addition to these, thermal pollution and the depletion of dissolved oxygen aggravate the already worsened condition of the water bodies. Water pollution can also indirectly occur as an offshoot of soil pollution – through surface runoff and leaching to groundwater.

Noise pollution, soil pollution and light pollution too are the damaging the environment at an alarming rate. Noise pollution include aircraft noise, noise of cars, buses, and trucks, vehicle horns, loudspeakers, and industry noise, as well as high-intensity sonar effects which are extremely harmful for the environment.

Soil pollution, which can also be called soil contamination, is a result of acid rain, polluted water, fertilizers etc., which leads to bad crops. Soil contamination occurs when chemicals are released by spill or underground storage tank leakage which releases heavy contaminants into the soil. These may include hydrocarbons, heavy metals, MTBE, herbicides, pesticides and chlorinated hydrocarbons.

Light Pollution includes light trespass, over-illumination and astronomical interference.

Whereas the pollution that we speak is not only outdoor but also to be considered in indoor environment.

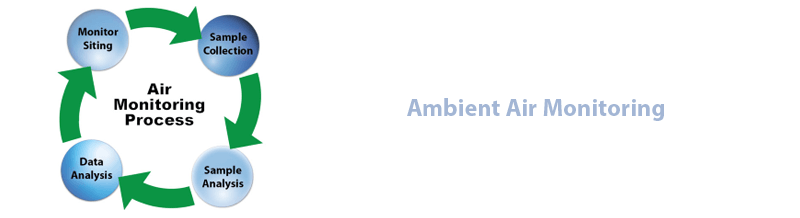

Ambient Air Monitoring

Ambient Monitoring is the systematic, long-term assessment of pollutant levels by measuring the quantity and types of certain pollutants in the surrounding, outdoor air. Air quality monitoring is carried out to assess the extent of pollution, ensure compliance with national legislation, evaluate control options, and provide data for air quality modeling.

The locations for monitoring stations depend on the purpose of the monitoring. Most monitoring networks are designed with human health objectives in mind. Once data are collected from a monitoring system, they must be stored in data management systems and databases. Subsequently, the data must be retrieved and analyzed to see what they reveal about the effectiveness of regulatory standards, the accuracy of modeling, impacts on health endpoints, and as an overall way of assessing

Stack Monitoring

Emissions Testing, otherwise referred to as Stack Sampling or Stack Monitoring, is the experimental process for evaluating the characteristics of industrial waste gas stream emissions into the atmosphere. Materials emitted to the air from these sources can be solid, liquid, or gas; organic or inorganic.

The effluent pollutants emitted to the atmosphere from a source may contain many different pollutant materials. Effluent measurements and sampling procedures follow specific test methods and protocols to ensure representative and accurate emission data. Test methods are pollutant specific, sometimes industry specific and originate from a variety of source.

There are several reasons for obtaining source emission data on the type and amounts of materials being emitted from industrial stacks:

- to determine if a process unit is in compliance with existing or proposed emission regulations;

- to ascertain the economics of materials or product losses from a source;

- to obtain relevant data which can facilitate the selection and design of control equipment;

- to test the efficiency of installed control equipment;

- to allow control of a process by continuous or frequent observation of one or more constituents in the stack gas stream;

- to provide more accurate data to develop air resources management programs, control regulations and inventories;

- to calibrate continuous monitors.

Indoor Air Monitoring

Common issues associated with IAQ include:

Improper or inadequately maintained heating and ventilation systems

Contamination by construction materials, glues, fiberglass, particle boards, paints, chemicals, etc.

Increase in number of building occupants and time spent indoors

Causes

IAQ problems result from interactions between building materials and furnishing, activities within the building, climate, and building occupants. IAQ problems may arise from one or more of the following causes:

Indoor environment – inadequate temperature, humidity, lighting, excessive noise

Indoor air contaminants – chemicals, dusts, moulds or fungi, bacteria, gases, vapours, odours

Insufficient outdoor air intake

Contaminants

Carbon dioxide (CO2), tobacco smoke, perfume, body odours – from building occupants

Dust, fiberglass, asbestos, gases, including formaldehyde – from building materials

Toxic vapours, volatile organic compounds (VOCs) – from workplace cleansers, solvents, pesticides, disinfectants, glues

Gases, vapours, odours – off-gas emissions from furniture, carpets, and paints

Dust mites – from carpets, fabric, foam chair cushions

Microbial contaminants, fungi, moulds, bacteria, – from damp areas, stagnant water and condensate pans

Ozone – from photocopiers, electric motors, electrostatic air cleaners

Noise level monitoring

Purpose:

This revised amendment requires that employees be placed in a hearing conservation program if they are exposed to average noise levels of 85 dB or greater during an 8 hour workday. In order to determine if exposures are at or above this level, it may be necessary to measure or monitor the actual noise levels in the workplace and to estimate the noise exposure or “dose” received by employees during the workday.

When it is necessary:

Noise monitoring or measuring must be conducted only when exposures are at or above 85 dB. Factors which suggest that noise exposures in the workplace may be at this level include employee complaints about the loudness of noise, indications that employees are losing their hearing, or noisy conditions which make normal conversation difficult. The employer should also consider any information available regarding noise emitted from specific machines. In addition, actual workplace noise measurements can suggest whether or not a monitoring program should be initiated.

How noise is Measured ?

Basically, there are two different instruments to measure noise exposures: the sound level meter and the dosimeter.

A sound level meter is a device that measures the intensity of sound at a given moment whereas a dosimeter is like a sound level meter except that it stores sound level measurements and integrates these measurements over time, providing an average noise exposure reading for a given period of time, such as an 8-hour workday.

Clean room validation

A clean room is a modular environment in which the following environmental factors are kept under control; temperature, airborne particulates, microbes, relative humidity, differential pressure, and air flow.

Clean room Validation is performed for a variety of reasons. To ensure that the design of the facility is fit for its intended purpose; to ensure that the facility, equipment, and environment meets User Requirement Specifications (URS); to ensure that the facility, equipment, and environment meet defined regulatory requirements; to ensure that the facility, equipment, and its environment function together as a system to meet defined standards.

Food handler’s hygiene

A food handler is anyone who works in a food business and who either handles food or surfaces that are likely to be in contact with food such as cutlery, plates and bowls. A food handler may do many different things for a food business. Examples include making, cooking, preparing, serving, packing, displaying and storing food. Food handlers can also be involved in manufacturing, producing, collecting, extracting, processing, transporting, delivering, thawing or preserving food.

What If a food handler has a food-borne illness?

What If a food handler has skin injuries or sores or is otherwise unwell?

What If a food handler knows or suspects he or she might have contaminated some food?

So, Hygiene Practices of food handlers is of really high importance

Microbiological tests for working surfaces, processing equipment and utensils

- Surface contamination monitoring

- Evaluating spray drift

- Understanding the nature of particulate deposition

- Monitoring cleaning efficiency

- Answering a range of other monitoring questions

Analysis is routinely performed on a range of organic and inorganic air contaminants and a wide variety of microbiological contaminants